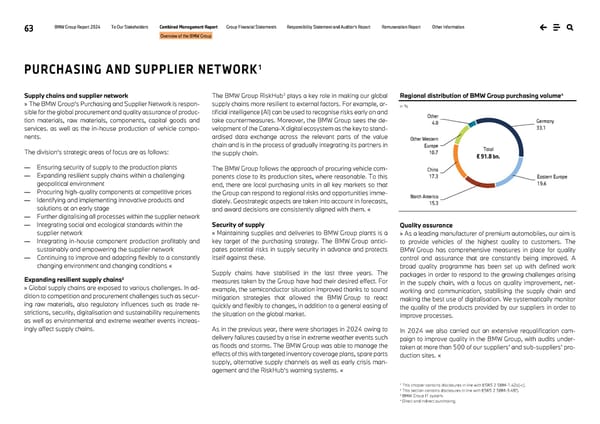

63 BMW Group Report 2024 To Our Stakeholders Combined Management Report Group Financial Statements Responsibility Statement and Auditor’s Report Remuneration Report Other Information Overview of the BMW Group PURCHASING AND SUPPLIER NETWORK 1 Supply chains and supplier network » The BMW Group’s Purchasing and Supplier Network is respon- sible for the global procurement and quality assurance of produc- tion materials, raw materials, components, capital goods and services. as well as the in-house production of vehicle compo- nents. The division’s strategic areas of focus are as follows: — Ensuring security of supply to the production plants — Expanding resilient supply chains within a challenging geopolitical environment — Procuring high-quality components at competitive prices — Identifying and implementing innovative products and solutions at an early stage — Further digitalising all processes within the supplier network — Integrating social and ecological standards within the supplier network — Integrating in-house component production profitably and sustainably and empowering the supplier network — Continuing to improve and adapting flexibly to a constantly changing environment and changing conditions « Expanding resilient supply chains2 » Global supply chains are exposed to various challenges. In ad- dition to competition and procurement challenges such as secur- ing raw materials, also regulatory influences such as trade re- strictions, security, digitalisation and sustainability requirements as well as environmental and extreme weather events increas- ingly affect supply chains. The BMW Group RiskHub3 plays a key role in making our global supply chains more resilient to external factors. For example, ar- tificial intelligence (AI) can be used to recognise risks early on and take countermeasures. Moreover, the BMW Group sees the de- velopment of the Catena-X digital ecosystem as the key to stand- ardised data exchange across the relevant parts of the value chain and is in the process of gradually integrating its partners in the supply chain. The BMW Group follows the approach of procuring vehicle com- ponents close to its production sites, where reasonable. To this end, there are local purchasing units in all key markets so that the Group can respond to regional risks and opportunities imme- diately. Geostrategic aspects are taken into account in forecasts, and award decisions are consistently aligned with them. « Security of supply » Maintaining supplies and deliveries to BMW Group plants is a key target of the purchasing strategy. The BMW Group antici- pates potential risks in supply security in advance and protects itself against these. Supply chains have stabilised in the last three years. The measures taken by the Group have had their desired effect. For example, the semiconductor situation improved thanks to sound mitigation strategies that allowed the BMW Group to react quickly and flexibly to changes, in addition to a general easing of the situation on the global market. As in the previous year, there were shortages in 2024 owing to delivery failures caused by a rise in extreme weather events such as floods and storms. The BMW Group was able to manage the effects of this with targeted inventory coverage plans, spare parts supply, alternative supply channels as well as early crisis man- agement and the RiskHub’s warning systems. « Regional distribution of BMW Group purchasing volume4 in % Quality assurance » As a leading manufacturer of premium automobiles, our aim is to provide vehicles of the highest quality to customers. The BMW Group has comprehensive measures in place for quality control and assurance that are constantly being improved. A broad quality programme has been set up with defined work packages in order to respond to the growing challenges arising in the supply chain, with a focus on quality improvement, net- working and communication, stabilising the supply chain and making the best use of digitalisation. We systematically monitor the quality of the products provided by our suppliers in order to improve processes. In 2024 we also carried out an extensive requalification cam- paign to improve quality in the BMW Group, with audits under- taken at more than 500 of our suppliers’ and sub-suppliers’ pro- duction sites. « 1 This chapter contains disclosures in line with ESRS 2 SBM-1.42a)-c). 2 This section contains disclosures in line with ESRS 2 SBM-3.48f). 3 BMW Group IT system. 4 Direct and indirect purchasing. Germany 33.1 Eastern Europe 19.6 North America 15.3 China 17.3 Other Western Europe 10.7 Other 4.0 Total € 91.8 bn.

BMW Group Report 2024 Page 62 Page 64

BMW Group Report 2024 Page 62 Page 64