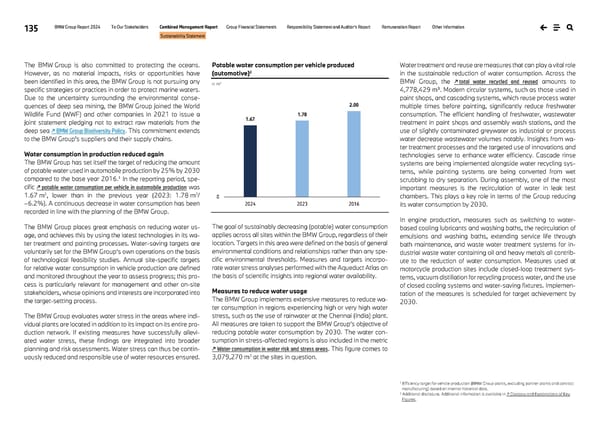

135 BMW Group Report 2024 To Our Stakeholders Combined Management Report Group Financial Statements Responsibility Statement and Auditor’s Report Remuneration Report Other Information Sustainability Statement The BMW Group is also committed to protecting the oceans. However, as no material impacts, risks or opportunities have been identified in this area, the BMW Group is not pursuing any specific strategies or practices in order to protect marine waters. Due to the uncertainty surrounding the environmental conse- quences of deep sea mining, the BMW Group joined the World Wildlife Fund (WWF) and other companies in 2021 to issue a joint statement pledging not to extract raw materials from the deep sea ↗ BMW Group Biodiversity Policy. This commitment extends to the BMW Group's suppliers and their supply chains. Water consumption in production reduced again The BMW Group has set itself the target of reducing the amount of potable water used in automobile production by 25% by 2030 compared to the base year 2016.1 In the reporting period, spe- cific ↗ potable water consumption per vehicle in automobile production was 1.67 m3, lower than in the previous year (2023: 1.78 m3/ –6.2%). A continuous decrease in water consumption has been recorded in line with the planning of the BMW Group. The BMW Group places great emphasis on reducing water us- age, and achieves this by using the latest technologies in its wa- ter treatment and painting processes. Water-saving targets are voluntarily set for the BMW Group’s own operations on the basis of technological feasibility studies. Annual site-specific targets for relative water consumption in vehicle production are defined and monitored throughout the year to assess progress; this pro- cess is particularly relevant for management and other on-site stakeholders, whose opinions and interests are incorporated into the target-setting process. The BMW Group evaluates water stress in the areas where indi- vidual plants are located in addition to its impact on its entire pro- duction network. If existing measures have successfully allevi- ated water stress, these findings are integrated into broader planning and risk assessments. Water stress can thus be contin- uously reduced and responsible use of water resources ensured. Potable water consumption per vehicle produced (automotive)2 in m3 The goal of sustainably decreasing (potable) water consumption applies across all sites within the BMW Group, regardless of their location. Targets in this area were defined on the basis of general environmental conditions and relationships rather than any spe- cific environmental thresholds. Measures and targets incorpo- rate water stress analyses performed with the Aqueduct Atlas on the basis of scientific insights into regional water availability. Measures to reduce water usage The BMW Group implements extensive measures to reduce wa- ter consumption in regions experiencing high or very high water stress, such as the use of rainwater at the Chennai (India) plant. All measures are taken to support the BMW Group’s objective of reducing potable water consumption by 2030. The water con- sumption in stress-affected regions is also included in the metric ↗ Water consumption in water risk and stress areas. This figure comes to 3,079,270 m3 at the sites in question. Water treatment and reuse are measures that can play a vital role in the sustainable reduction of water consumption. Across the BMW Group, the ↗ total water recycled and reused amounts to 4,778,429 m³. Modern circular systems, such as those used in paint shops, and cascading systems, which reuse process water multiple times before painting, significantly reduce freshwater consumption. The efficient handling of freshwater, wastewater treatment in paint shops and assembly wash stations, and the use of slightly contaminated greywater as industrial or process water decrease wastewater volumes notably. Insights from wa- ter treatment processes and the targeted use of innovations and technologies serve to enhance water efficiency. Cascade rinse systems are being implemented alongside water recycling sys- tems, while painting systems are being converted from wet scrubbing to dry separation. During assembly, one of the most important measures is the recirculation of water in leak test chambers. This plays a key role in terms of the Group reducing its water consumption by 2030. In engine production, measures such as switching to water- based cooling lubricants and washing baths, the recirculation of emulsions and washing baths, extending service life through bath maintenance, and waste water treatment systems for in- dustrial waste water containing oil and heavy metals all contrib- ute to the reduction of water consumption. Measures used at motorcycle production sites include closed-loop treatment sys- tems, vacuum distillation for recycling process water, and the use of closed cooling systems and water-saving fixtures. Implemen- tation of the measures is scheduled for target achievement by 2030. 1 Efficiency target for vehicle production (BMW Group plants, excluding partner plants and contract manufacturing) based on internal historical data. 2 Additional disclosure. Additional information is available in ↗ Glossary and Explanations of Key Figures. 1.67 1.78 2.00 0 2024 2023 2016

BMW Group Report 2024 Page 134 Page 136

BMW Group Report 2024 Page 134 Page 136