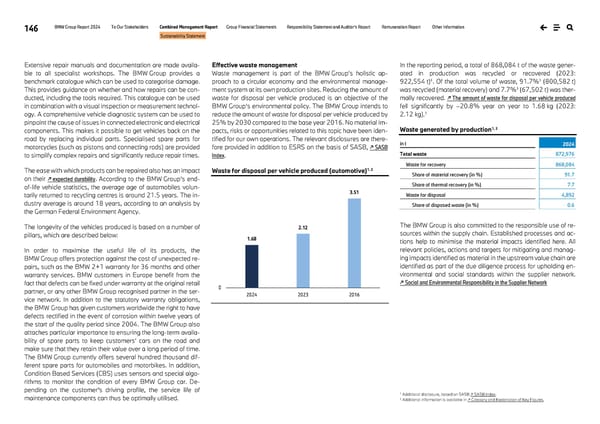

146 BMW Group Report 2024 To Our Stakeholders Combined Management Report Group Financial Statements Responsibility Statement and Auditor’s Report Remuneration Report Other Information Sustainability Statement Extensive repair manuals and documentation are made availa- ble to all specialist workshops. The BMW Group provides a benchmark catalogue which can be used to categorise damage. This provides guidance on whether and how repairs can be con- ducted, including the tools required. This catalogue can be used in combination with a visual inspection or measurement technol- ogy. A comprehensive vehicle diagnostic system can be used to pinpoint the cause of issues in connected electronic and electrical components. This makes it possible to get vehicles back on the road by replacing individual parts. Specialised spare parts for motorcycles (such as pistons and connecting rods) are provided to simplify complex repairs and significantly reduce repair times. The ease with which products can be repaired also has an impact on their ↗ expected durability. According to the BMW Group’s end- of-life vehicle statistics, the average age of automobiles volun- tarily returned to recycling centres is around 21.5 years. The in- dustry average is around 18 years, according to an analysis by the German Federal Environment Agency. The longevity of the vehicles produced is based on a number of pillars, which are described below: In order to maximise the useful life of its products, the BMW Group offers protection against the cost of unexpected re- pairs, such as the BMW 2+1 warranty for 36 months and other warranty services. BMW customers in Europe benefit from the fact that defects can be fixed under warranty at the original retail partner, or any other BMW Group recognised partner in the ser- vice network. In addition to the statutory warranty obligations, the BMW Group has given customers worldwide the right to have defects rectified in the event of corrosion within twelve years of the start of the quality period since 2004. The BMW Group also attaches particular importance to ensuring the long-term availa- bility of spare parts to keep customers’ cars on the road and make sure that they retain their value over a long period of time. The BMW Group currently offers several hundred thousand dif- ferent spare parts for automobiles and motorbikes. In addition, Condition Based Services (CBS) uses sensors and special algo- rithms to monitor the condition of every BMW Group car. De- pending on the customer's driving profile, the service life of maintenance components can thus be optimally utilised. Effective waste management Waste management is part of the BMW Group’s holistic ap- proach to a circular economy and the environmental manage- ment system at its own production sites. Reducing the amount of waste for disposal per vehicle produced is an objective of the BMW Group’s environmental policy. The BMW Group intends to reduce the amount of waste for disposal per vehicle produced by 25% by 2030 compared to the base year 2016. No material im- pacts, risks or opportunities related to this topic have been iden- tified for our own operations. The relevant disclosures are there- fore provided in addition to ESRS on the basis of SASB, ↗ SASB Index. Waste for disposal per vehicle produced (automotive)1, 2 In the reporting period, a total of 868,084 t of the waste gener- ated in production was recycled or recovered (2023: 922,554 t)1. Of the total volume of waste, 91.7%1 (800,582 t) was recycled (material recovery) and 7.7%1 (67,502 t) was ther- mally recovered. ↗ The amount of waste for disposal per vehicle produced fell significantly by –20.8% year on year to 1.68 kg (2023: 2.12 kg).1 Waste generated by production1, 2 in t 2024 Total waste 872,976 Waste for recovery 868,084 Share of material recovery (in %) 91.7 Share of thermal recovery (in %) 7.7 Waste for disposal 4,892 Share of disposed waste (in %) 0.6 The BMW Group is also committed to the responsible use of re- sources within the supply chain. Established processes and ac- tions help to minimise the material impacts identified here. All relevant policies, actions and targets for mitigating and manag- ing impacts identified as material in the upstream value chain are identified as part of the due diligence process for upholding en- vironmental and social standards within the supplier network. ↗ Social and Environmental Responsibility in the Supplier Network 1 Additional disclosure, based on SASB ↗ SASB Index. 2 Additional information is available in ↗ Glossary and Explanation of Key Figures. 1.68 2.12 3.51 0 2024 2023 2016

BMW Group Report 2024 Page 145 Page 147

BMW Group Report 2024 Page 145 Page 147