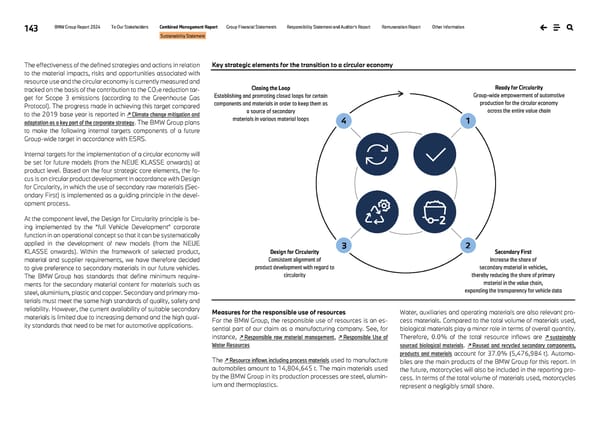

143 BMW Group Report 2024 To Our Stakeholders Combined Management Report Group Financial Statements Responsibility Statement and Auditor’s Report Remuneration Report Other Information Sustainability Statement The effectiveness of the defined strategies and actions in relation to the material impacts, risks and opportunities associated with resource use and the circular economy is currently measured and tracked on the basis of the contribution to the CO2e reduction tar- get for Scope 3 emissions (according to the Greenhouse Gas Protocol). The progress made in achieving this target compared to the 2019 base year is reported in ↗ Climate change mitigation and adaptation as a key part of the corporate strategy. The BMW Group plans to make the following internal targets components of a future Group-wide target in accordance with ESRS. Internal targets for the implementation of a circular economy will be set for future models (from the NEUE KLASSE onwards) at product level. Based on the four strategic core elements, the fo- cus is on circular product development in accordance with Design for Circularity, in which the use of secondary raw materials (Sec- ondary First) is implemented as a guiding principle in the devel- opment process. At the component level, the Design for Circularity principle is be- ing implemented by the “full Vehicle Development” corporate function in an operational concept so that it can be systematically applied in the development of new models (from the NEUE KLASSE onwards). Within the framework of selected product, material and supplier requirements, we have therefore decided to give preference to secondary materials in our future vehicles. The BMW Group has standards that define minimum require- ments for the secondary material content for materials such as steel, aluminium, plastic and copper. Secondary and primary ma- terials must meet the same high standards of quality, safety and reliability. However, the current availability of suitable secondary materials is limited due to increasing demand and the high qual- ity standards that need to be met for automotive applications. Measures for the responsible use of resources For the BMW Group, the responsible use of resources is an es- sential part of our claim as a manufacturing company. See, for instance, ↗ Responsible raw material management, ↗ Responsible Use of Water Resources The ↗ Resource inflows including process materials used to manufacture automobiles amount to 14,804,645 t. The main materials used by the BMW Group in its production processes are steel, alumin- ium and thermoplastics. Water, auxiliaries and operating materials are also relevant pro- cess materials. Compared to the total volume of materials used, biological materials play a minor role in terms of overall quantity. Therefore, 0.0% of the total resource inflows are ↗ sustainably sourced biological materials. ↗ Reused and recycled secondary components, products and materials account for 37.0% (5,476,984 t). Automo- biles are the main products of the BMW Group for this report. In the future, motorcycles will also be included in the reporting pro- cess. In terms of the total volume of materials used, motorcycles represent a negligibly small share. Ready for Circularity Group-wide empowerment of automotive production for the circular economy across the entire value chain Closing the Loop Establishing and promoting closed loops for certain components and materials in order to keep them as a source of secondary materials in various material loops 4 1 Secondary First Increase the share of secondary material in vehicles, thereby reducing the share of primary material in the value chain, expanding the transparency for vehicle data Design for Circularity Consistent alignment of product development with regard to circularity 3 2 Key strategic elements for the transition to a circular economy

BMW Group Report 2024 Page 142 Page 144

BMW Group Report 2024 Page 142 Page 144